Oil Transportation

Oil Transportation

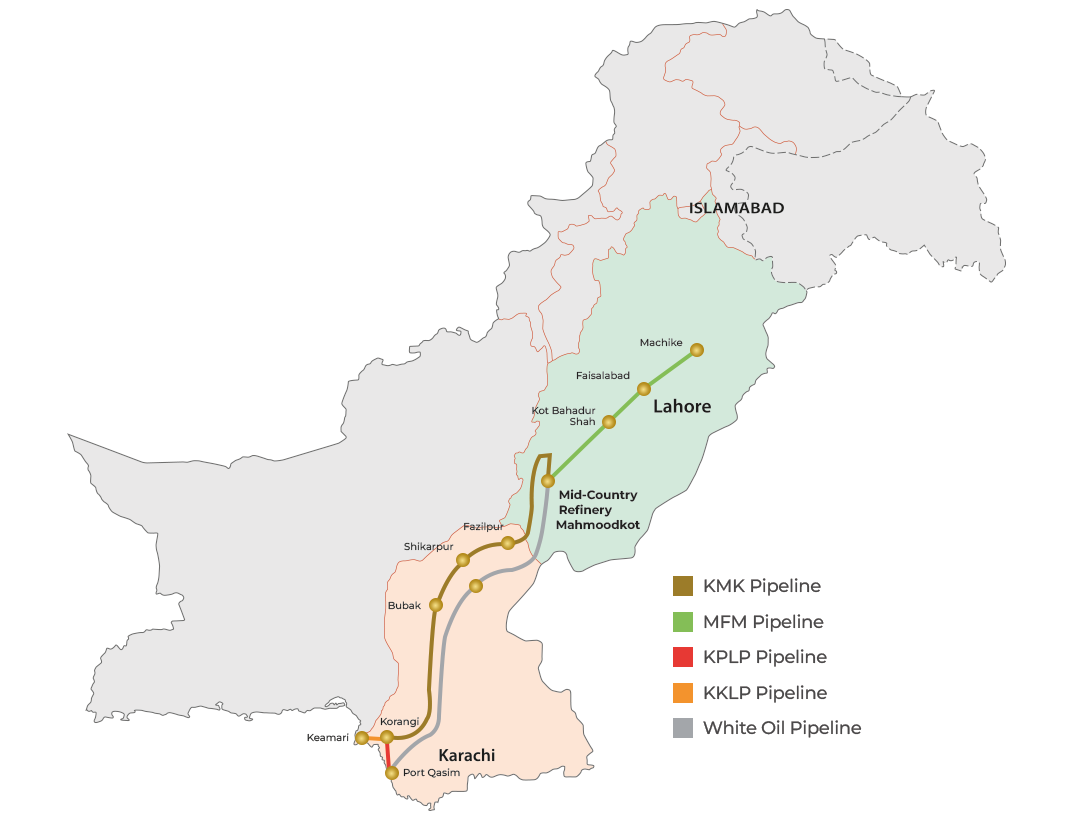

Spanning over 2000 kilometres from Karachi up to Machhike near Lahore, PARCO’s cross-country network of pipelines, including those of its subsidiary – Pak Arab Pipeline Company (PAPCO), play a vital role in oil and transportation across the nation. The pipelines’ presence has led to a significant reduction in environmental harm and road congestion by substituting thousands of tank lorries. This underground river of fluid energy has practically eliminated surface pollution, thefts, product contamination and significantly reduced noise and fatalities related to road transport.

PARCO owns and operates the following pipelines:

Oil Transportation Pipeline System

Karachi-Mahmoodkot Pipeline

- Commissioned in: 1997

- Length: 362 km

- Annual pumping capacity: 3.7 million tons

Mahmoodkot-Faisalabad–Machike (MFM) Pipeline

- Commissioned in: 1997

- Length: 362 km

- Annual pumping capacity: 3.7 million tons

Korangi-Port Qasim Link (KPLP) Pipeline

- Commissioned in: 2006

- Length: 22 km

- Annual pumping capacity: 5.97 million tons

Keamari-Korangi Link (KKLP) Pipeline

• Commissioned in: 1981

• Length: 18.4 Km

• Route: Begins from TS-1, Keamari Station

• Annual pumping capacity: 10.85 MMT

White Oil Pipeline (WOP)

- Commissioned in: 2005

- Length: 786 km

- Annual pumping capacity: 12 million tons

Korangi

Bubak

Shikarpur

Fazilpur

Mid-Country Refinery Mahmoodkot

Keamari

Port Qasim

Kot Bahadur Shah

Faisalabad

Machike

Keamari-Korangi Link (KKLP) Pipeline

• Commissioned in: 1981

• Length: 18.4 Km

• Route: Begins from TS-1, Keamari Station

• Annual pumping capacity: 10.85 MMT

PARCO’s pipeline system also has the capability to receive local crude directly through decanting facilities and High Speed Diesel from local refineries, such as Pakistan Refinery Limited (PRL) and National Refinery Limited (NRL). Additionally, the system acts as a debottlenecking facility for Kaemari Port in Karachi by receiving imported crude oil and PAPCO’s High Speed Diesel from Keamari Terminal Station. The crude oil is then pumped to the Mid-Country Refinery, at Mahmoodkot via the KMK Pipeline, while the diesel is pumped through KPLP into the White Oil Pipeline system.

PARCO employs cutting-edge technology and sophisticated monitoring systems to ensure the integrity and safety of its pipelines. The advanced Supervisory Control and Data Acquisition (SCADA) system continuously monitors the pipelines, detecting any abnormalities or leaks, enabling immediate response and preventive measures. This ensures the protection of the environment as well as the safety of the company’s workforce and surrounding communities.

In 2022, both the White Oil Pipeline (operated by PAPCO) and the Mahmoodkot-Faisalabad-Machike Pipeline (operated by PARCO) underwent an upgrade at a cost of USD 200 million. This upgrade allowed for the simultaneous transportation of Motor Gasoline in addition to High-Speed Diesel from Karachi to Machike (near Lahore). This project has built additional pumping and storage capacity to seamlessly run the country’s fuel supply chain and meet the ever-growing demand for fuel.

PARCO’s storage facilities are crucial in maintaining a continuous flow of the economy. They strategically store substantial amounts of crude oil and refined petroleum products to guarantee a steady fuel supply whenever needed. The PARCO Pipeline and Storage network can uphold oil reserves over 1.5 million metric tons, encompassing stocks in storage tanks across multiple stations and the line-fill.